Filament review: Printing with potatoes?

26 April 2015 at 7:58 pm

One thing that fascinate people about 3D printing is the fact that the PLA plastic we often use as material is made from Corn. Now you can get a bioplastic made from potatoes as well! In this review of the bioplastic called Biome3D I'll highlight how it prints and how it differs from other materials. It has some quite useful properties!

The majority of PLA available comes from the company Natureworks. They sell the raw material to plastic manufacturers that add colorants and other chemicals to achieve their desired properties. The Corn based PLA most often used for 3D printing is the Ingeo 4043d grade but you can find other variants and producers.

The potato based bioplastic I'm testing here, is made in the UK by the company Biome Plastics and it's primarily sold through the website 3DomFilaments. I initially purchased some samples, but I picked up a couple more rolls since I wanted to test some more.

Not as brittle

The first thing I noticed is that it's nowhere as brittle as PLA. This is a major advantage. When you take a piece of the filament and bend it, it acts more like ABS. It bends and becomes more white in color. You won't break it until you bend 10-12 times. The material is strong and allows quite some bending before it breaks. It's not anywhere as tough as PET though, but much more suited than corn based PLA for applications that will be experiencing any degree of flexing. It is still stiff and solid and it barely shrinks at all.

When printing, the layers bond really well and I can extrude it nicely all the way down to 175C - a very low temperature for my printer. It also has a nice, matte shine to it and theres basically no smell when heating the material. What I find the most fascinating about this material is how different it looks from other filaments when extruded!

Different consistency

When this material flows out of the nozzle, it behaves different than other 3D printing filaments I have. If you just push material out of the extruder, it will not hang as a nice, thin string. Instead, it will become a "lump" that gets a "skin", but keeps filling from the inside with hot material until the lump becomes so heavy that it falls off and create a new lump. Check the video below to see what I mean.

In other words, this material seem to "store" heat longer than other filaments. You can very much feel that if you try to squeeze one of the lumps of plastic that fall down.

The Biome 3D filament goes soft at 80-90 degrees, but you can print it at much lower temperatures than most other materials. As can be seen from all the horizontal stripes in the picture at the top here, cooling is essential. My printer is currently in the middle of a conversion to dual Flex3Drive (Writeup on this brilliant tech soon!) so I barely have any cooling. This shows clearly as lines along the prints. Lowering the temperature helps a lot and it prints well down to rather low temperatures.

Post processing!

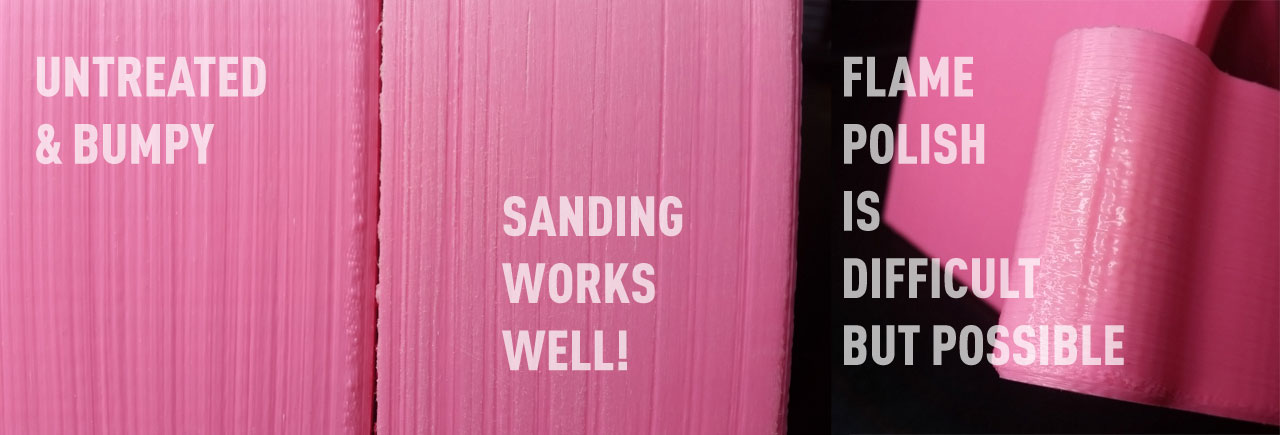

This stuff can be sanded! Normal PLA will melt as soon as you start sanding or polishing it, but the Biome material seems to have a high enough Glass Transition temp that you can actually work it quite a bit before it deforms. That means that normal sanding is possible, but also tumbling with various mediums.

As can be seen above - my lack of cooling causes stripes in the print. I didn't sand the piece in the middle all the way down as the grooves were quite deep, but you can see how well it works. PLA will heat up and melt as soon as you sand it, but the Biome 3D filament holds up well as long as you don't repeatedly sand the same spot. I was even able to sand it using a Dremel as long as I kept moving to allow some cooling. It is impossible to polish the material to a shine like you can for ABS as it's matte by nature. I have not tested how well paint sticks, but I'll do a test and add that here later.

I can't find a proper datasheet, but the ability to sand the parts made me think that the Glass Transition temp was higher than the 70C typical for other PLA and lower than the 110C for ABS. I did some testing by submerging a printed part in 70C tap water. This revealed that it does indeed deform at this temperature and it also deformed at 60C. At 55C the object held up, so a Glass Transition temperature of 60C seems likely. That's actually lower than some PLA variants and makes it unsuited for parts that are exposed to heat. In other words - this won't replace ABS as a way to print spare parts for your dishwasher or similar tasks.

I also tried flame polishing the material. It does bring out a gloss but it's extremely hard to not apply too much heat. Since the heat builds up inside the material, I managed to get what looked like a perfect finish, but then after a few seconds it looked like above. The heat in the material kept melting it… I also tried to treat it with acetone, but it has no visual effect. It does however seem to dissolve the plastic to some degree.

All golden?

Now this seems all very cool, but there must be some negative things also? Of course there is, but they're not that bad. If you follow the manufacturers recommendation and use a heated bed at 60-70C, you'll see the prints sag at the bottom (Elephant's foot). I've actually seen this in all my prints to some degree, despite lowering the bed temperature to 40C. Like said before - a lot of cooling is required when printing with this plastic as heat is "stored" in the plastic. In other words - extra fans may be required.

Another thing that might be more of a problem is the inconsistencies I found with the spooled material. The diameter was quite consistent (+/- 0.2mm on my 2.85mm filament), but I had one case where it was way above normal (3.2mm). The material is spooled in a way so that it does not unspool perfectly. Towards the end of the roll it actually managed to pull my extruder back across half the build platform when the steppers turned off. This is probably easy to remedy and they've just started producing filament so they'll surely fix this. They should however also fix this:

Melted onto the filament was a lump of plastic from the production. This would have ruined the print on any printer. I happened to notice it, but you really don't want to see stuff like this. The material comes in the colors white, black, red, yellow, blue, green and pink so the selection isn't exactly stellar, but this is sufficient for many. Only opaque colors exist for now, so no translucent yet. When I purchased, I was first sent 1.75mm plastic despite ordering 3mm. As a compensation, they gave me half a roll of another color - so while the webshop isn't completely routined, they do offer good customer service.

In other words - I like the filament, but they need to ensure the quality is consistent. With that, I think this can be a good replacement for the fossil ABS filaments. I especially like that you can sand it and that it's more flexible than ABS/PLA!

BAMM settings for Biome3D filament

The BAM Makeblock printer has a Flex3Drive extruder with a Hexagon nozzle. I use the following settings with this material:

- Temperature: 175-190C

- Speed: 50-100mm/sec

- Retraction: 2.5mm

- Extruder tension: normal

- Heated bed: 40C

- Fan: full (& then some)