Filament review: NinjaFlex rocks!

06 October 2014 at 8:25 pm

I've been meaning to test the flexible NinjaFlex materials, but having an Ultimaker made that impossible. Flexible filaments and bowden tubes don't play well as the friction of the plastic makes it curl and stop. With the new BAM printer, I have a direct extruder mounted just above the hotend. This is the ideal setup for flexible filaments and with the newly fitted Bulldog XL extruder it's a snap to change materials.

It's incredibly strong!

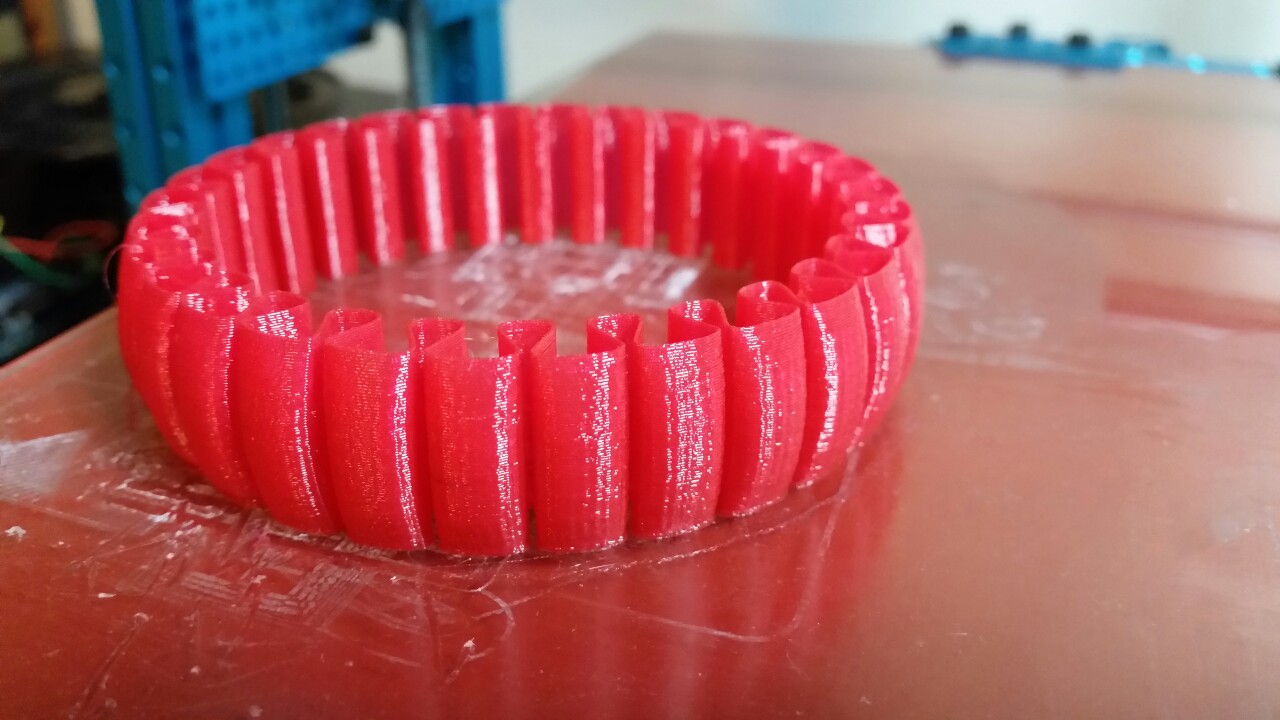

I can't quite get over how solid objects printed with NinjaFlex are. They're soft in that they can be curled together, but will regain their shape easily. If you print a single wall of NinjaFlex (0.4mm thick) it will take a lot of force to tear it apart. My first print was exactly that - a single wall stretchlet.

My first reaction was how soft it felt? Then I tried to tear it apart and I failed? I gave it to my teenager son, but he also couldn't tear it apart. I then put my foot on it and pulled with full force by two hands… It expanded to 5-8 times the original length and then snapped just like a rubber band. Only when it snapped (main image) could you see any sign of layer separation. Amazing stuff!

Uses for flexible materials

The elasticity offers some very desirable properties. For instance, a 2-perimeter bracelet can also be used as a hair band in a crisis. It is perfect for making noise dampening rubber feet for your Makeblock printer, BMX grips, phone bumpers and RC tyres. Fenner Drives that makes the NinjaFlex filament, recently came out with more colors including silver & gold! I'm really looking forward to play more with this filament. I picked mine up from E3D along with other parts, but you can find it many places.

BAM printer settings

The BAM Makeblock printer has a BulldogXL extruder with a Hexagon nozzle. I use the following settings with Ninjaflex:

- Temperature: 220C

- Speed: <= 30mm/sec

- Retraction: 2.5mm @ 20mm/sec

- Extruder tension: screws 2mm out (almost none as friction is extremely high)

- Heated bed: 40C

- Fan: none

If you go faster than 30mm/sec, the plastic will curl up inside the BulldogXL extruder.